Background : The site had experienced multiple failures on the outgoing boosted pipework to the fire hydrant system causing major loss of water and loss of the fire hose-reel system to the prison.

Issues : On investigation it was found that the flexible pipework connector was operating at the limit of its pressure rating and had been installed in such a way as to cause the connector to rub against a raised edge on the PVC flange and cause premature failure of the connector. A temporary repair was carried out to enable the system to operate.

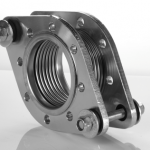

Solution : With the assistance of a specialist manufacturer we specified and installed a custom designed, 25.0 Bar rated, stainless steel flexible connector and also replaced a 2.5m length of PVC-U pipework with 25.0 Bar rated stainless steel. The new pipework was reinsulated and trace heating refitted to match the existing pipework.