We were called to investigate a repeated history of expansion vessel diaphragm failures. An Ultrasound examination of the vessel thickness revealed thinning of the metal and a subsequent internal examination showed severe corrosion with a sharp edge puncturing the diaphragm. The thinning of the vessel represented a risk of vessel failure and the safe option was to replace the vessel.

All posts by elseyadcock

Office Block – London Cold water booster set

The hydro-pneumatic accumulator fitted on a cold water booster set in a roof top failed due to hydraulic shock caused by a lack of regular maintenance. The fact that the vessel failed was bad enough but the ensuing flooding of the top two floors caused £1000’s of damage. Routine regular maintenance would have avoided this situation.

166 apartments in Manchester

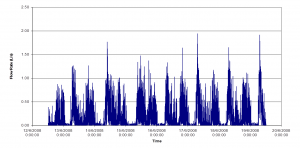

Flow meter readings were obtained from a block of 166 apartments which measured a peak demand of 2.0 litres per second. National guides widely used in the industry calculated a duty flow requirement of 30.0 litres per second, over sizing the pump set by fifteen times! Subsequently over sizing the delivery pipe work system and electrical supply.

The energy consumption of the original 3 pump fixed speed booster set over a one week period was 924kWh. The pump set was replaced with a 5 pump variable speed booster set with each pump being much smaller than the original fixed speed pumps used. Power consumption over a week for the new pump set was reduced to 134kWh, a saving of 790kWh per week of wasted energy! This equates to a saving of over 18 tonnes of CO2 per annum, and saving £3,000 per year on the electricity bill.

Acorn completed a £128,000 contract for a University on Merseyside

Acorn completed a £128,000 contract for a University on Merseyside. The project involved the installation of a bespoke AquaTech Pressmain HY9 variable speed booster set.

As well as supplying the HY9AV, an 8” ABS ring main (approx. 100m of pipe was installed, much of it at high level) around the Hydraulics Laboratory with various ‘take offs’ to run a selection ofexperiments where the movement of water is required. These vary from powering both Francisand Pelton turbines, to supplying water to experiments where wave patterns are used to create an ‘hydraulic jump’ to simulate the effects of a tsunami.

The work was completed over a ten week period, with commissioning taking place at the end of the project.

The Tate & Lyle Estate – East London

Acorn was called to the Tate & Lyle Estate in East London after their incumbent pump maintenance contractor failed to solve or respond to an emergency situation on a Pullen Hydropak water booster set. The water booster set had a catalogue of faults including burnt out and leaking pumps, a failed and leaking accumulator and non functioning controls.

The unit was also over sized for the application and beyond economical repair. As the estate had no water a temporary supply was connected, whilst a new Aquatech Pressmain HY3AV 10-6 booster was built and then installed just seven days from receipt of an order, normally this would take 4 or 5 weeks.