“I joined AGM in August 1997 as a pipe fitter working in the mechanical workshop, building their Aquatech Pressmain brand of packaged water booster sets and pressurisation units, and overhauling old pumps.

The company moved to AGM House, London Rd, Copford in 2000, and shortly afterwards I was promoted to Mechanical Workshop Supervisor. I then began taking on several more responsibilities including checking and signing off units on the production line.

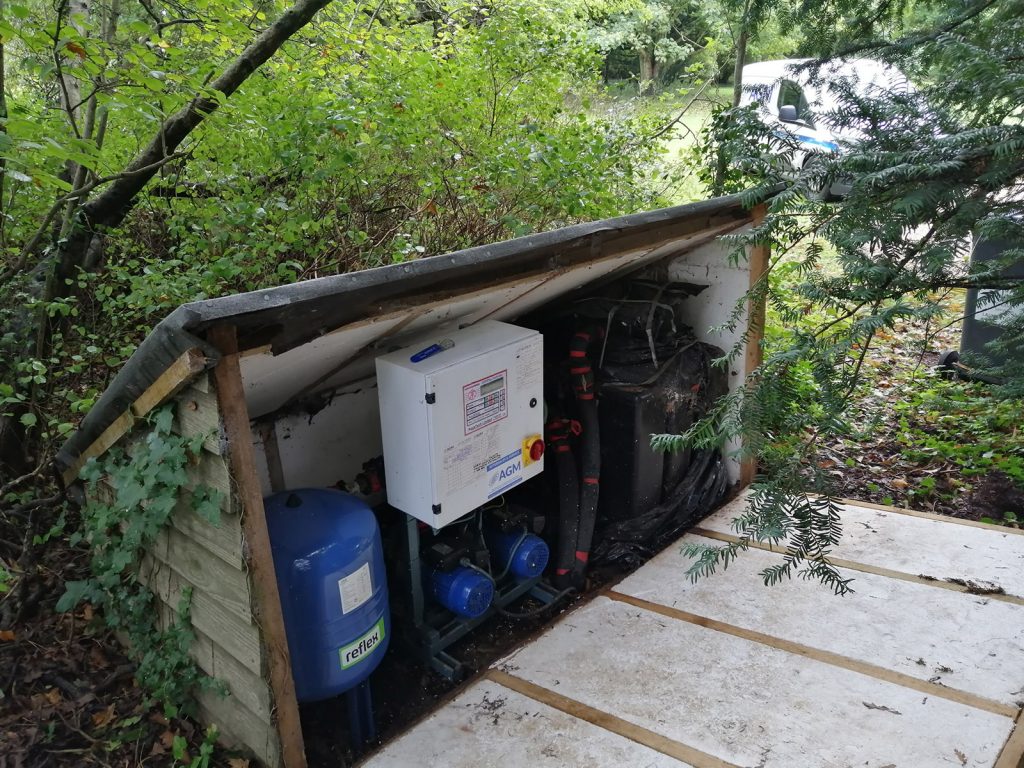

Four years later I was promoted to Works Foreman, were my role comprised of talking to customers and processing their orders, ordering stock, arranging couriers for dispatch, handing out work for workshop staff, testing units and much more. In 2009 to the present, I moved from production to AGM Pressurisationl Services as an Installation Engineer, where my responsibilities include servicing, breakdowns, warranties and installation works on many different manufacturers’ makes and models of pressurisation units and booster sets and more.

I enjoy working at many different sites around the country, every day is different: a different location, a different plant room, a different property type and different people. On one occasion I flew to the Falkland Islands with the RAF to do some install work on the District Heating System on the air base out there.

In this constantly changing industry I look forward to gaining more experience with more and more new system and unit types, which always keeps things interesting. I have been very fortunate throughout the last 20 or so years that I have worked with some very knowledgeable, friendly and helpful colleagues and it’s always been good to feel part of the team.”

Ben Brotherton – AGM Installation Engineer