AGM were asked by CBRE Managed services Ltd, to provide a reliable and robust solution for the bank’s Head Office in London. They required continuous low temperature hot water for the heating system along with a continuous, chilled water supply to the air conditioning in the server rooms.

AGM were asked by CBRE Managed services Ltd, to provide a reliable and robust solution for the bank’s Head Office in London. They required continuous low temperature hot water for the heating system along with a continuous, chilled water supply to the air conditioning in the server rooms.

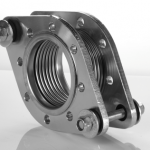

To guarantee this level of continuous service, and considering the limitations of the space available in the plant room, AGM used their own Aquatech Pressmain brand of products. Providing a solution of two AP7 pressurisation units, one running, one in duty standby mode for the hot water and another two set up in the same way for the chilled water system. All four units are in use ensuring equal wear, controlled by a changeover panel.

The four units are housed in a bespoke framework designed and manufactured by AGM to fit in the restricted space within the plant room, at the same time ensuring easy access for maintenance.

AGM installed the units and they will be maintained by them under their maintenance contact with 24/7 call out.

If you have a project which needs this level of service and would like AGM to help, please contact the project department on 01206 215176.